Modern logistics demands a comprehensive transformation through intelligent warehousing solutions. Our analysis demonstrates how integrating advanced AI, machine learning, robotics, and IoT creates measurable operational advantages. This strategic framework delivers scalable, data-driven ecosystems that transform traditional warehousing into competitive market differentiators.

Quick Guide

- Key Technologies Driving Smart Warehousing

- Operational Benefits of Smart Systems

- Implementation Challenges

- Future Development Trends

- Real-World Implementation Examples

- Conclusion

Key Technologies Driving Smart Warehousing

AI and Machine Learning Integration

Smart warehousing operations leverage AI as their cornerstone technology, fundamentally transforming basic processes into intelligent, data-driven workflows. Machine learning systems perform sophisticated analysis of historical data patterns to:

- Optimize inventory levels across warehouse operations

- Generate accurate demand forecasts

- Prevent stock shortages through predictive analytics

- Streamline resource allocation based on operational patterns

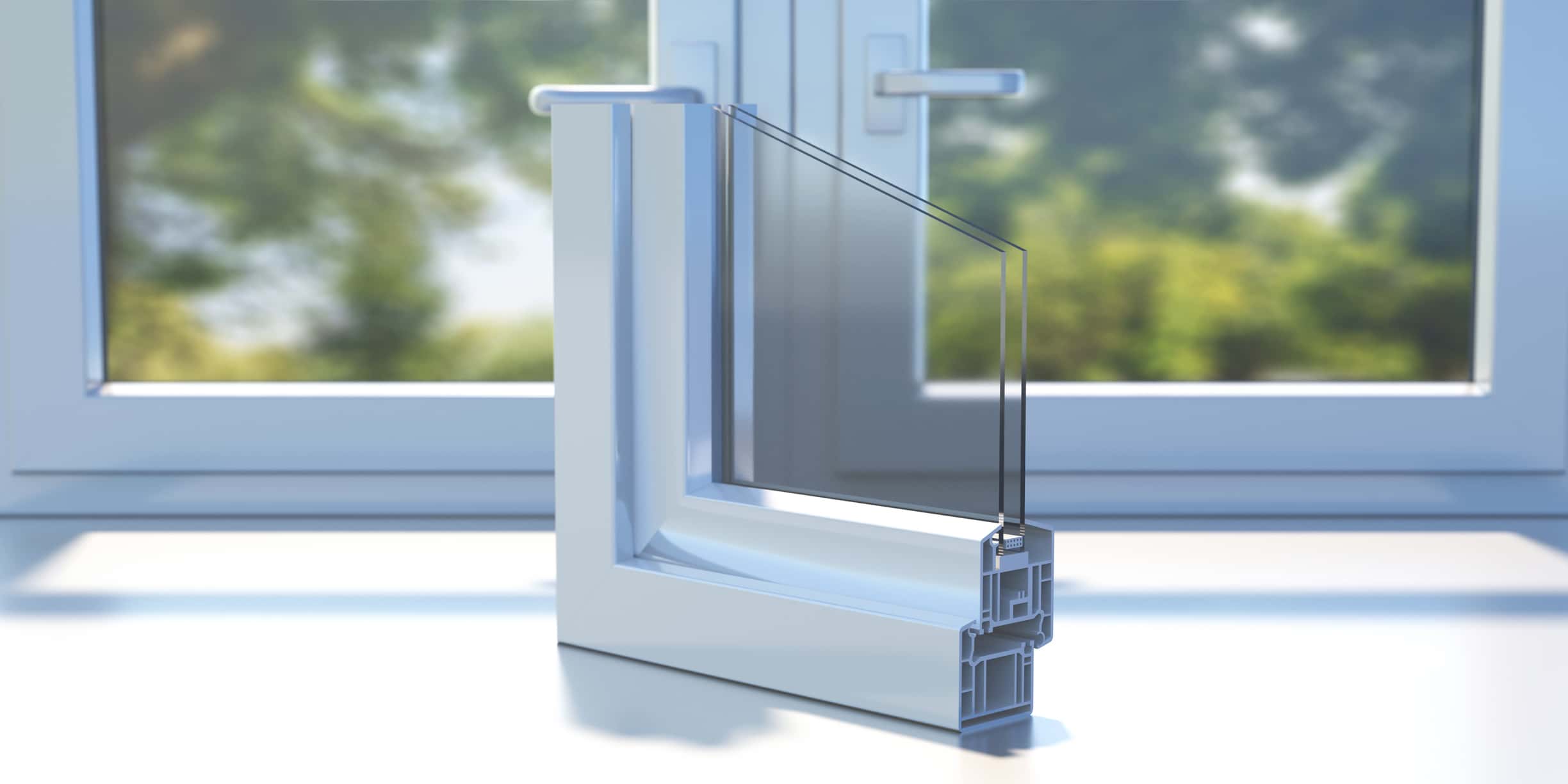

Robotic Process Enhancement

Modern warehouses utilize sophisticated robotics, including Automated Guided Vehicles, robotic picking arms, and surveillance drones. These systems operate continuously, handling routine tasks like inventory movement and order picking with precision. The implementation of robotics has transformed traditional warehouse operations, reducing manual errors while significantly improving operational speed and accuracy.

IoT Device Implementation

Smart sensors and RFID tags form an interconnected network throughout the warehouse, enabling real-time tracking capabilities. These devices monitor inventory locations, stock levels, and environmental conditions, providing warehouse managers with instant access to critical operational data. This constant flow of information ensures accurate inventory management and swift response to changing conditions.

Operational Benefits of Smart Systems

Efficiency Improvements

AI-powered automation enables continuous operation, significantly reducing processing times for essential tasks. The system handles picking, packing, and shipping operations with increased speed and precision, meeting growing customer expectations while maintaining service quality. This enhanced efficiency translates directly to improved warehouse performance and customer satisfaction.

Cost Management Advantages

Automated systems reduce reliance on manual processes, leading to substantial operational savings. The reduction in human error combined with increased processing speed creates a more cost-effective warehouse environment. These savings allow businesses to invest in further technological improvements while maintaining competitive pricing structures.

Safety and Accuracy Enhancement

Robotic systems handle potentially hazardous tasks, creating a safer work environment for human staff. The precision of automated processes ensures consistent accuracy in inventory management and order fulfillment. This dual benefit of improved safety and reliability strengthens overall warehouse operations.

Implementation Challenges

Financial Considerations

The initial investment required for smart warehouse systems presents a significant hurdle, particularly for smaller operations. Companies must carefully evaluate the long-term benefits against substantial upfront costs, considering factors like return on investment and operational improvements.

Workforce Transition Management

As automation increases, companies must address workforce adaptation needs. This includes developing comprehensive training programs and creating new roles that complement automated systems. Successful implementation requires careful management of this transition to maintain workforce stability and productivity.

Security Protocol Development

Connected warehouse systems require robust cybersecurity measures to protect operations. Companies must implement comprehensive security protocols to safeguard sensitive data and maintain system integrity. This includes regular updates, monitoring systems, and employee security training.

Future Development Trends

Autonomous Vehicle Integration

The roadmap incorporates advanced autonomous vehicle solutions and automated delivery systems. Drone-based logistics enhance operational capabilities, while integrated autonomous operations drive efficiency improvements. These innovations ensure sustained competitive advantage.

Sustainability Initiatives

Intelligent energy management systems optimize resource utilization while minimizing environmental impact. Advanced waste reduction protocols enhance operational sustainability, while comprehensive monitoring ensures environmental compliance. This approach aligns operational excellence with environmental responsibility.

Human-AI Collaborative Systems

Future warehouse operations will focus on effective collaboration between human workers and AI systems. This partnership approach maximizes the strengths of both human insight and machine precision, creating more efficient and adaptable warehouse environments.

Real-World Implementation Examples

Amazon’s Advanced Robotics

Amazon demonstrates leadership in warehouse automation through its comprehensive robotics program. Their automated systems handle complex inventory movement tasks, significantly improving fulfillment speeds and operational efficiency. This implementation showcases the practical benefits of automated warehouse systems at scale.

Conclusion

Looking ahead, the warehousing sector faces continued evolution as emerging technologies reshape fulfillment capabilities. Industry analysts project that by 2027, over 60% of warehouse operations will incorporate some form of AI-enabled automation. However, success will ultimately depend on organizations’ ability to cultivate workforces that can effectively leverage these advanced systems while maintaining focus on core business objectives and customer relationships.

For warehouse operators and logistics providers, the path forward requires strategic investment in both technological infrastructure and human capital development. Those who successfully navigate this dual challenge position themselves to capture increasing market share in an industry where operational excellence increasingly defines competitive advantage.